|

Shandong XinKaite Bearing Co., Ltd.

|

large stock low price deep groove ball bearing 6204 used as Conveyor Accessories from bearing manufacturer

| Payment Terms: | T/T,L/C |

| Place of Origin: | Shandong, China (Mainland) |

|

|

|

| Add to My Favorites | |

| HiSupplier Escrow |

Product Detail

deep groove ball bearing 6204

Integrity promise Connaught, intentions to do everything.

Export manufacturer

Passed Certifications - ISO9001:2015

TN Product tested by National Coal Science Institute and Provincial Quality Inspection Center

Single-row deep groove ball bearings are the most common type of rolling bearings. Their use is very widespread.

In addition to open type bearings, these bearings often have steel shields or rubber seals installed on one or both sides and are prelubricated with grease. Also, snap rings are sometimes used on the periphery. As to cages, pressed steel ones are the most common.

For big deep groove ball bearings, machined brass cages are used.

Machined cages are also used for high speed applications.

Types

Basic type; With snap ring groove on the outer ring (-N); With one shield (-Z) on one side or two shields (-2Z) on both sides; With one seal (-RS) on one side or two seals (-2RS) on both sides.

All of Our products are made of Chrome Steel GCr15, with grinding groove and superfinishing technology.

Application

Mining machine, conveyor machine, Engineering Machinery, Agricultural Machinery, Construction Machinery, textile, chemical, auto motor, Transportation Vehicles, General industrial Equipment, etc.

Catalog of Deep groove ball bearing

Professional brings quality, detail creates success

XKTE bearing's most fundamental difference is:

The other manufacturers make products considering the price cheap, but we make products considering the service life. Each of the idler roller bearings we produce is fully implemented in the national standard. XKTE bearings exist for their quality and brand. You can deny our price, but you can never find out our products' defects in quality. XKTE conveying machinery bearing, a big brand, is worthy of your trust.

First, the identification of the bearing

Formal manufacturers use laser engraving. The stamps are deep, have significant dents with hand touch, good-looking, with no breakpoints, and are never disappeared. This obviously improves the bearing grade.

The use of bearing retainer

Bearing retainer selection is very important. Because once too much dust stuck into the bearing, the retainer will be first worn. If the bearing retainer is broken, the bearing will be directly broken. Imported bearings use big rivets to thicken retainers. XKTE bearing is completely in accordance with the process of imported production, so each piece of ours is made to a high quality, and guaranteed to operate for thirty thousand hours.

Selection of nylon retainer

Nylon retainer bearing is often used in the mine. Nylon retainer has better anti-stuck performance and wider range of temperature than iron retainer. In the underground its anti-static performance is also better. To get safety certificate for coal mining products must use nylon retainer KA bearing. The selection of nylon retainer is crucial to KA idler roller bearing, while the material of nylon retainer must be pure and has enough toughness and strength, because the retainer will get very soft if it is made of bad material or mixed material, thus to make no anti-stuck performance within the bearing.

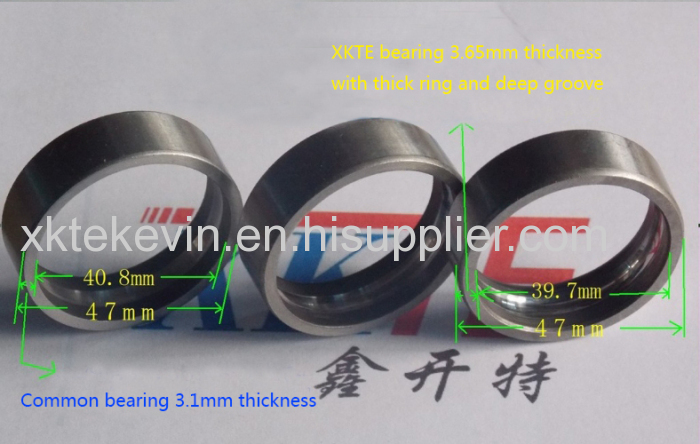

The ring is the main part and the important part of the idler roller bearing. Best idler roller bearing has deep groove ball, and large clearance. But deep groove doesn't mean to dig the channel with a simple way of enlarge the steel ball. The thickness of the bearing is certain, so to get the ball big and the groove deep will shorten service life. Our XKTE bearing uses way of thickening ring to get the standard of deep groove and large clearance, improves the anti-stuck performance, and effectively increases the service life.

Bearing material and hardness

Good idler roller bearing must be made of bearing steel, named "High Carbon Chromium Bearing Steel (Fully quenched class) GCr15". At present the standard hardness of idler roller bearing is 60-65 degree, while hardness of ring is 61-62 degree, andball is 64-65 degree.

The simple way to identify idler roller bearing is to see if its hardness is over 60 degree, because only bearing steel can get over this degree.

Grease selection of roller bearing

Many customers ignore this most critical point. The thirty-thousands-hours operation is a very long term. This has to be guaranteed by enough quality and quantity grease. And this should also be taken into account of working in different seasons.

Special note: please choose special high temperature grease if working environment is over 120 °C for long time or low temperature grease if it below -20 °C.

Reference:

The installation of conveyor idler bearing

As the conveyor idler bearing has high precision, it calls great requirements for the installation and use. If we donot pay enough attention to it, that would be a great damage to the conveyor idler bearing: the lifetime may be shortened, the related components would be damaged. Generally speaking, the accidents of conveyor idler bearing are caused by the wrong installation and use, therefore, we could increase the lifetime of the conveyor idler bearing if it is installed and used correctly.

Matters need attention:

While installing the conveyor idler bearing, the most important thing is to keep the conveyor idler bearing and related components clean and use proper installing tools.

1. Clean the work zone and use clean installing tools;

2. We should use assistant tools with good plasticity which donot fall off easily;

3. Confirm all the components are qualified;

4. We should break and open the seal while using it;

5. Keep the conveyor idler bearing clean during the whole installation;

6. Generally speaking, we donot need to wash off the slushing oil the conveyor idler bearing carries unless the lubrication grease is needed, we could install it as usual.

Other Products

Package:

1. Industrial packaging : Single box + outer carton + pallets

2. Neutral Packing:

Tube package + outer carton + pallets

Tube package + middle box + outer carton + pallets

3. As buyer's request

Payment methods:

1) TT, 30% deposit , 70% before shippment.

2) L/C at sight. (high bank charge, not suggest , but acceptable )

3) 100% Western Union in advance. (specially for air shipment or small amount)

Shipment | For small orders,we send by express UPS,DHL,FEDEX, or EMS with Thracking number. For big quantity, we will ship by air or by sea. |

Delivery date | Normally stock within 3-7 days. Bulk quantity within 30 days. |

Payment terms | T/T L/C |

2. For small amount, we accept Western Union | |

Samples Policy : | Small sample free and bulk sample cost needed and freight collected. We will reduct this part expense from the total value when place order. |

Started 2006, We are a manufacture of industrial Bearing in Liaocheng Shandong, concentrates on manufacturing industrial bearing, mainly used in conveying equipment, machinery, textile, chemical, auto motor and so on. Especially bearing for conveyor, which make us become one of well-known enterprise in China. We have 26 production lines, mainly produce deep groove ball bearing, spherical roller bearing, TN Nylon cage bearing and sealed bearing.

All of Our products are made of Chrome Steel GCr15, with grinding groove and superfinishing technology. Supply ability is about 20000 Pieces / per Day. We have our own brand XKTE, and we can also provide OEM service.

FAQ:

I couldn't find a design to fit my application in your catalog. Can you help me design a bearing?

Yes, technical expertise is available to assist you with engineering design for custom products. Available options include, but are not limited to, custom rings, retainers, balls, shields, lubricants, and packaging. We look forward to working with you to satisfy your rotary motion requirements.

What causes bearing noise?

Bearing noise is a function of both the bearing and the way it is used. Some external factors that affect bearing noise include lubricant type, excessive bearing load, and improper installation. Once the abnormal noise occurred, you can contact our engineers, we will help you find the reasons and provide the appropriate solutions.

What is the difference between using a shield or a seal as a ball bearing closure?

Shields or seals are often installed to retain lubricant and to prevent contamination from entering the bearing. While a shield contacts the outer ring and does not come in contact with the inner ring, the seal generally comes in contact with both the inner and outer rings. Torque or drag is lower with a shield than with a seal. Alternately, the seal provides a higher degree of protection from contamination. Shields and seals are available in a variety of materials and configurations.

XKTE developed a serious of sealing methods for different applications. Please contact a XKTE engineer for technical assistance with any special requirements.

Why choose us ?

1. professional commitment to conveying machinery bearing, leading enterprise of conveyor

machinery bearing in China.

2. With background of about 10 years

3. Strict Inspection ,and the best quality price with reasonable price bearings provided .

4. OEM service provided.

5. Delivery products from our factory warehouse , short delivery time.

86-15688862750

02 at xinkaite.com

www dot xinkaite dot com