|

Shandong XinKaite Bearing Co., Ltd.

|

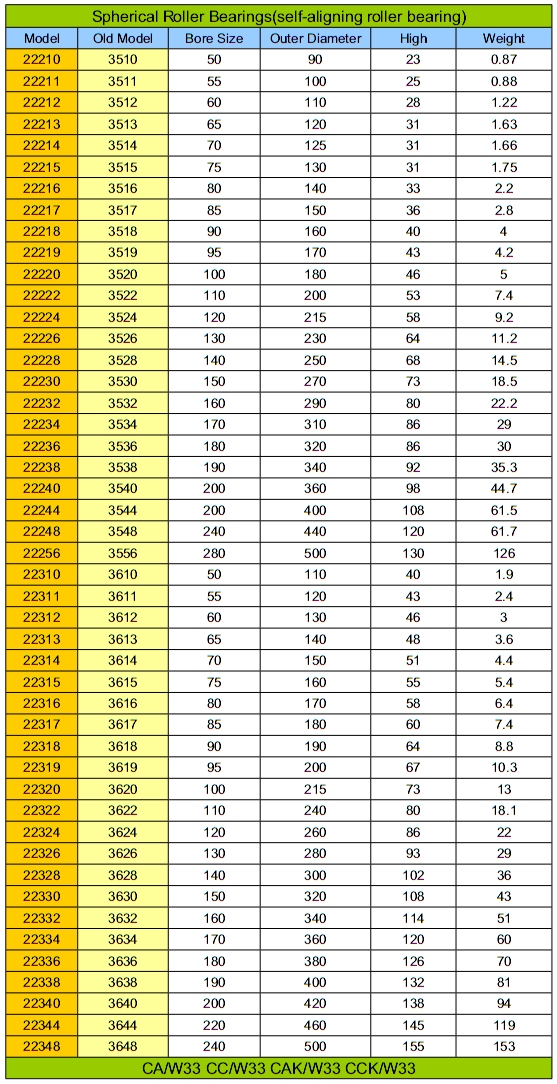

Double rows spherical roller bearing 22210CA 22210 CAK 22210CC for mining machine from china bearing distributor

| Payment Terms: | T/T,L/C |

| Place of Origin: | Shandong, China (Mainland) |

|

|

|

| Add to My Favorites | |

| HiSupplier Escrow |

Product Detail

professional commitment to conveying machinery bearing

Integrity promise Connaught, intentions to do everything.

Export manufacturer

Spherical roller bearings have two columns of roller, mainly bear radial, meanwhile can bear axial load from any direction. Spherical roller bearings have high radial load capacity, which is especially suitable for work under the heavy load or vibration load, but can't afford to pure axial load. This kind of bearing outer ring raceway is spherical shape, so the self-aligning properties good performance, to compensate concentricity error.

Product Name | XKTE Spherical roller bearing 22210 |

Material | Chrome Steel GCr15 |

Bore Size: | 50mm |

Outside Diameter: | 90mm |

Width: | 23mm |

Weight: | 0.87kg |

Number of Row: | Double Row |

Cage | Copper Cage/Steel Cage |

Precision Rating | P0 P6 P5 P4 |

Vibration Level | V1, V2, V3, V4 |

Noise Level | Z1, Z2, Z3, Z4 |

Clearance | C0, C2, C3, C4 |

Feature | Long Life, Low Noise, Anti-sticking |

Lubrication | Grease/Oil Lubrication |

Service | OEM is acceptable |

Certificate: | ISO9001:2015 |

Main market | Europe, North and South ofAmerica, Asia and so on |

Place of Origin: | Shandong,China(Mainland) |

Package | Neutral Packing |

Application | Mining&Construction, Papermaking machinery, Vibrating screens, Shakers, Conveyors, Speed reducers transmissions,and other heavy machinery. |

Product Features

Load capacity is larger

Good impact resistance

Can bear a greater axial load

The operating temperature of the bearing is low

Can adapt to the requirement of high speed

Symmetrical drum roller freedom combined with concave outer ring groove plate.

Cage:

CC: Steel plate stamping

CC type bearing inner ring is the feature of no guard and adopts the stamping steel cage,

CA: Brass cage

CA model, XKTE bearing characteristics of the inner ring both have guard cage and used car system entities

Application:

Mining & Construction,

crusher,

Conveyors,

railway vehicle axle,

Papermaking machinery,

Vibrating screens,

printing machinery,

Shakers,

Speed reducers transmissions,

and other heavy machinery.

Reference:

Manufacture of idler roller bearings

Idler roller bearings in the use, often appear to be the phenomenon of damage, usually caused by the use of too long, and of course there are other reasons. In order to avoid being injured, it should be put in place the relevant work. Right, conservative and stable will response to the bearing life of the machining process. With the deterioration of metallurgical technology, the quality of the original talent lost better. The bearing is in the process of production, through a lot of cold and hot processing, in order to satisfy the small quantity, high frequency, high quality requirements, bearing steel should have good processing function. To solve the heat reaction and reject one-way thrust ball bearing quality and grinding of bearing force, and often has a more direct contact. As a result, the adoption of the stress in the shape of the demolition can be slowed down, to ensure that the demolition of the function. Loss of torque on a single holder increased by 30 to 40%, and the loss of torque of one-way thrust ball bearing increased by 50 to 65%. Manufacturer of idler roller bearing and accessories should be done normal through forging, turning, grinding and heat treatment, such as multi-channel processing of disassembly. Thin-walled bearing steel is under the use of the angle of the normal form to reach HRC61~65, the ability to make a one-way thrust ball bearings to get a higher contact fatigue strength and wear resistance.

Our Other Products

Package:

1. Industrial packaging : Single box + outer carton + pallets

2. Neutral Packing:

Tube package + outer carton + pallets

Tube package + middle box + outer carton + pallets

3. As buyer's request

Payment methods:

1) TT, 30% deposit , 70% before shippment.

2) L/C at sight. (high bank charge, not suggest , but acceptable )

3) 100% Western Union in advance. (specially for air shipment or small amount)

Shipment | For small orders,we send by express UPS,DHL,FEDEX, or EMS with Thracking number. For big quantity, we will ship by air or by sea. |

Delivery date | Normally stock within 3-7 days. Bulk quantity within 30 days. |

Payment terms | T/T L/C |

2. For small amount, we accept Western Union | |

Samples Policy : | Small sample free and bulk sample cost needed and freight collected. We will reduct this part expense from the total value when place order. |

Started 2006, We are a manufacture of industrial Bearing in Liaocheng Shandong, concentrates on manufacturing industrial bearing, mainly used in conveying equipment, machinery, textile, chemical, auto motor and so on. Especially bearing for conveyor, which make us become one of well-known enterprise in China. We have 26 production lines, mainly produce deep groove ball bearing, spherical roller bearing, TN Nylon cage bearing and sealed bearing.

All of Our products are made of Chrome Steel GCr15, with grinding groove and superfinishing technology. Supply ability is about 20000 Pieces / per Day. We have our own brand XKTE, and we can also provide OEM service.

FAQ:

I couldn't find a design to fit my application in your catalog. Can you help me design a bearing?

Yes, technical expertise is available to assist you with engineering design for custom products. Available options include, but are not limited to, custom rings, retainers, balls, shields, lubricants, and packaging. We look forward to working with you to satisfy your rotary motion requirements.

What causes bearing noise?

Bearing noise is a function of both the bearing and the way it is used. Some external factors that affect bearing noise include lubricant type, excessive bearing load, and improper installation. Once the abnormal noise occurred, you can contact our engineers, we will help you find the reasons and provide the appropriate solutions.

What is the difference between using a shield or a seal as a ball bearing closure?

Shields or seals are often installed to retain lubricant and to prevent contamination from entering the bearing. While a shield contacts the outer ring and does not come in contact with the inner ring, the seal generally comes in contact with both the inner and outer rings. Torque or drag is lower with a shield than with a seal. Alternately, the seal provides a higher degree of protection from contamination. Shields and seals are available in a variety of materials and configurations.

XKTE developed a serious of sealing methods for different applications. Please contact a XKTE engineer for technical assistance with any special requirements.

Why choose us ?

1. professional commitment to conveying machinery bearing, leading enterprise of conveyor

machinery bearing in China.

2. With background of about 10 years

3. Strict Inspection ,and the best quality price with reasonable price bearings provided .

4. OEM service provided.

5. Delivery products from our factory warehouse , short delivery time.

86-15688862750

kevin at xinkaite.com

www dot xinkaite dot com