|

Shandong XinKaite Bearing Co., Ltd.

|

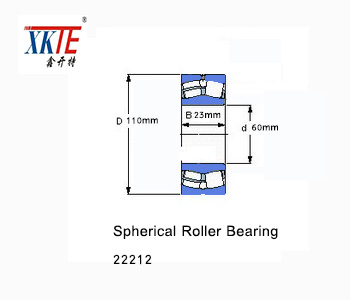

manufacture made XKTE brand spherical roller bearing 22212 with high quality used in industrial machine

| Payment Terms: | T/T,L/C,D/A,D/P,Paypal,Money Gram |

| Place of Origin: | Shandong, China (Mainland) |

|

|

|

| Add to My Favorites | |

| HiSupplier Escrow |

Product Detail

We are a manufacture of conveyor roller bearing, spherical roller bearing 22212 used in mining machine, industrial machine

Professional brings quality, detail creates success

A spherical roller bearing is a rolling-element bearing that permits rotation with low friction, and permits angular misalignment.

Typically these bearings support a rotating shaft in the [bore] of the inner ring that may be misaligned in respect to the outer ring. The misalignment is possible due to the spherical internal shape of the outer ring and spherical rollers.

Despite what their name may imply, spherical roller bearings are not truly spherical in shape. The rolling elements of spherical roller bearings are mainly cylindrical in shape, but have a profile that makes them appear like cylinders that have been slightly over-inflated

| Structure: | Spherical | Type: | Roller | Brand Name: | XKTE |

| Bore Size: | 0 - 60 mm | Outside Diameter: | 0 - 110 mm | Model Number: | 22212 |

| Precision Rating: | P0 P6 P5 | Seals Type: | Open | Number of Row: | Double Row |

| Place of Origin: | Shandong, China (Mainland) | Certification: | ISO9001:2015 | Material: | Chrome Steel GCR15 |

| Weight: | 1.22kg | Application: | Conveyors | Package: | Plastic Cover + Carton + Wooden Pallet |

| Lubrication: | Oil.greese | Service: | OEM Customized Services |

Products Feature

XKTE bearing's most fundamental difference is:

The other manufacturers make products considering the price cheap, but we make products considering the service life. Each of the idler roller bearings we produce is fully implemented in the national standard. XKTE bearings exist for their quality and brand. You can deny our price, but you can never find out our products' defects in quality. XKTE conveying machinery bearing, a big brand, is worthy of your trust.

Started 2006, We are a manufacture of industrial Bearing in Liaocheng Shandong, concentrates on manufacturing industrial bearing, mainly used in conveying equipment, machinery, textile, chemical, auto motor and so on. Especially bearing for conveyor, which make us become one of well-known enterprise inChina. We have 26 production lines, mainly produce deep groove ball bearing, spherical roller bearing, TN Nylon cage bearing and sealed bearing.

All of Our products are made of Chrome Steel GCr15, with grinding groove and superfinishing technology. Supply ability is about 20000 Pieces / per Day. We have our own brand XKTE, and we can also provide OEM service.

There are several pictures about our products and factory attached, please check them.

Our Services

1.High Speed,High Precision,Low Noise,Long Service Life;

2.Wide array of applications;

3.Large inventories;

4.Small order accept;

5.Competitive price;

6.Famous brand;

7.Require little maintenance;

8.OEM is supported

9.Our company insists on the "quality first, credit first" business ideas and our product specification is well-founded. We have a good reputation in the international market by our perfect service and sufficient supply.

FAQ:

I couldn't find a design to fit my application in your catalog. Can you help me design a bearing?

Yes, technical expertise is available to assist you with engineering design for custom products. Available options include, but are not limited to, custom rings, retainers, balls, shields, lubricants, and packaging. We look forward to working with you to satisfy your rotary motion requirements.

What causes bearing noise?

Bearing noise is a function of both the bearing and the way it is used. Some external factors that affect bearing noise include lubricant type, excessive bearing load, and improper installation. Once the abnormal noise occurred, you can contact our engineers, we will help you find the reasons and provide the appropriate solutions.

What is the difference between using a shield or a seal as a ball bearing closure?

Shields or seals are often installed to retain lubricant and to prevent contamination from entering the bearing. While a shield contacts the outer ring and does not come in contact with the inner ring, the seal generally comes in contact with both the inner and outer rings. Torque or drag is lower with a shield than with a seal. Alternately, the seal provides a higher degree of protection from contamination. Shields and seals are available in a variety of materials and configurations.

XKTE developed a serious of sealing methods for different applications. Please contact a XKTE engineer for technical assistance with any special requirements.

Why choose us ?

1. professional commitment to conveying machinery bearing, leading enterprise of conveyor machinery bearing inChina.

2. With background of about 10 years

3. Strict Inspection ,and the best quality price with reasonable price bearings provided .

4. OEM service provided.

5. Delivery products from our factory warehouse , short delivery time.

Delivery

Certification:

15688862750

kevin at xinkaite.com